Here’s a comprehensive overview of Hazard Identification and Risk Assessment (HIRA)—a fundamental and highly searchable workplace safety topic:

🔍 Hazard Identification and Risk Assessment (HIRA)

✅ Definition

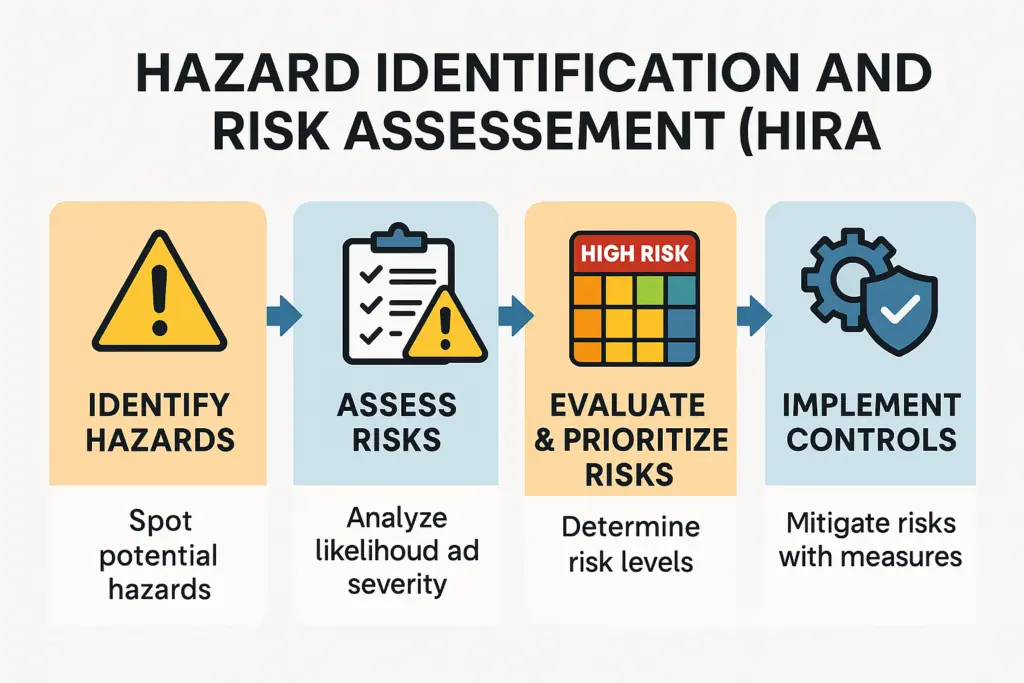

HIRA is a structured process used to identify hazards, analyze or evaluate the risk associated with those hazards, and then determine appropriate ways to eliminate or control the risk.

📌 1. Key Elements of HIRA

| Element | Description |

|---|---|

| Hazard | Anything with the potential to cause harm (e.g., chemical, mechanical, electrical, physical, ergonomic, biological). |

| Risk | The likelihood that a hazard will cause harm and the severity of that harm. |

| Risk Assessment | Process of evaluating risk based on likelihood and severity. |

| Control Measures | Actions to eliminate or minimize risks (e.g., engineering controls, PPE, training, safe work procedures). |

🛠️ 2. HIRA Process Steps

Identify Hazards

Observe the workplace

Review incident reports

Conduct job safety analysis (JSA)

Engage workers in walkthroughs

Assess Risks

Evaluate likelihood and severity

Use a risk matrix (e.g., 5×5 scale)

Evaluate & Prioritize Risks

Classify risks: Low, Medium, High, Extreme

Focus on high-priority risks first

Implement Controls

Apply the Hierarchy of Controls:

Elimination

Substitution

Engineering Controls

Administrative Controls

PPE

Review and Monitor

Regular review of risks

Update based on changes in process, equipment, or incidents

📊 3. Risk Matrix (Example: 5×5 Grid)

| Catastrophic | Major | Moderate | Minor | Negligible | |

|---|---|---|---|---|---|

| Certain | High Risk | High Risk | High Risk | Medium Risk | Medium Risk |

| Likely | High Risk | High Risk | Medium Risk | Medium Risk | Low Risk |

| Possible | High Risk | Medium Risk | Medium Risk | Low Risk | Low Risk |

| Unlikely | Medium Risk | Medium Risk | Low Risk | Low Risk | Very Low Risk |

| Rare | Medium Risk | Low Risk | Low Risk | Very Low | Very Low Risk |

🧩 4. Types of Hazards in HIRA

| Hazard Type | Examples |

|---|---|

| Physical | Noise, vibration, radiation, heat |

| Chemical | Acids, solvents, gases, dust |

| Biological | Bacteria, viruses, fungi |

| Ergonomic | Repetitive motion, poor posture |

| Mechanical | Unguarded machinery, moving parts |

| Electrical | Live wires, arc flash risk |

| Psychosocial | Stress, harassment, fatigue |

📘 5. Legal and Standard References

ISO 45001:2018 – Clause 6.1.2 (Hazard Identification & Assessment of Risks and Opportunities)

Factories Act (India) – Sections 7A & 41A

OSHA 29 CFR 1910 (USA)

BOCW Act – Rule 39 (Safety Officers)

🧠 6. Practical Uses of HIRA

Preparing Method Statements

Conducting Safety Walkdowns

Planning Work Permits (Hot work, Confined Space, etc.)

Developing Emergency Response Plans

Enhancing Training Programs

Would you like:

A HIRA template in Excel/Word?

A presentation format for training?

An activity-specific HIRA (e.g., scaffolding, excavation, electrical work)?

Or a HIRA register sample?